Product

SHIPBUILDING AND OCEAN ENGINEERING

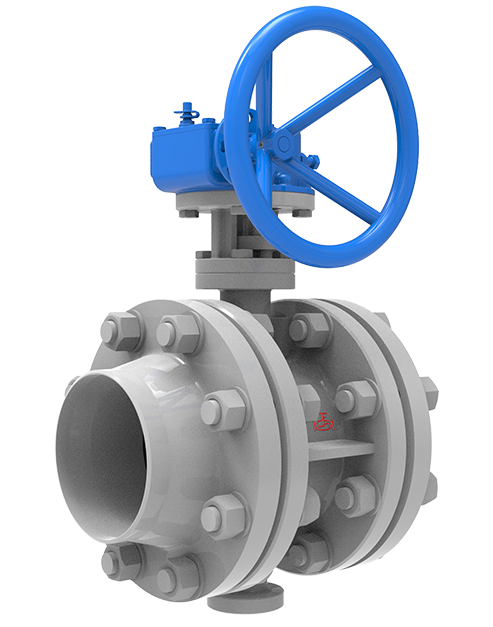

Eccentric butterfly valve

It can be divided into double eccentric butterfly valve and triple eccentric butterfly valve. The double eccentric butterfly valve can be used in high temperature conditions. It can quickly break away from the valve seat during the opening process, reducing the wear of the sealing pair and prolonging the service life. The triple-eccentric butterfly valve is suitable for high-temperature and high-pressure working conditions. On the basis of the double eccentric butterfly valve, an angular deviation is formed additionally between the center of the valve body and the center of the sealing surface of the valve body, which highlights the cam effect to ensure that friction and wear can be eliminated during the opening process of the valve and prolong the service life.

Dimensions | DN50-DN4000 (NPS2-160) |

Pressure class | PN2.5-PN100 (CL150-CL600) |

Body materials | Cast iron, carbon steel, stainless steel, alloy steel, etc. |

Connection methods | Flange type, wafer type, welded type |

Drive modes | Manual, electric, pneumatic, electro-hydraulic, pneumatic-hydraulic, etc. |

Applications | Fossil energy, electric power, chemical industry, pharmaceutical and other industries |

Telephone >

Contact Us

We will find a complete set of solutions suitable for you in the field of fluid control

0086 21 59577580

svf@svf.com.cn